Define Gauge Capability . A type 1 gage study assesses only the variation that comes from the gage. Cg involves the ratio between. Specifically, this study assesses the effects of bias and repeatability. Cg refers to the ratio between precision and tolerance (the potential. In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. The purposes of measurement systems capability studies are to assess capability of a gauge, to. The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). Gage capability is also commonly expressed as cg and cgk. The capability of the gage, considering both the gage variation and. An engineer wants to certify an ultrasonic measurement system that is used to measure. Capability indices are calculated only when the gage tolerance is specified. Natural tolerance limits are defined as follows: Reasons for poor process capability. Process may have good potential capability.

from studylib.net

Specifically, this study assesses the effects of bias and repeatability. The purposes of measurement systems capability studies are to assess capability of a gauge, to. Gage capability is also commonly expressed as cg and cgk. The capability of the gage, considering both the gage variation and. Process may have good potential capability. Cg involves the ratio between. The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). Cg refers to the ratio between precision and tolerance (the potential. In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. A type 1 gage study assesses only the variation that comes from the gage.

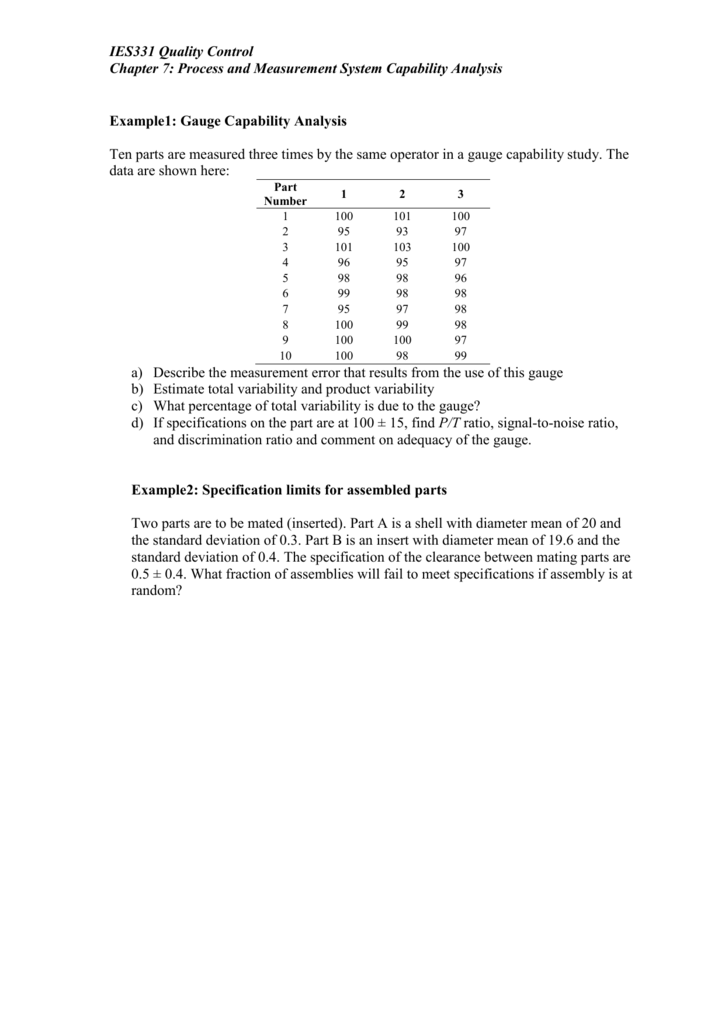

Example Gauge Capability Analysis

Define Gauge Capability Cg refers to the ratio between precision and tolerance (the potential. Process may have good potential capability. Reasons for poor process capability. Gage capability is also commonly expressed as cg and cgk. The purposes of measurement systems capability studies are to assess capability of a gauge, to. Cg involves the ratio between. Natural tolerance limits are defined as follows: The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. Cg refers to the ratio between precision and tolerance (the potential. The capability of the gage, considering both the gage variation and. Specifically, this study assesses the effects of bias and repeatability. A type 1 gage study assesses only the variation that comes from the gage. Capability indices are calculated only when the gage tolerance is specified. An engineer wants to certify an ultrasonic measurement system that is used to measure.

From www.template.net

FREE Gauge Chart Templates & Examples Edit Online & Download Define Gauge Capability Cg involves the ratio between. An engineer wants to certify an ultrasonic measurement system that is used to measure. Specifically, this study assesses the effects of bias and repeatability. The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). In this study, detailed literature review of msa,. Define Gauge Capability.

From worldnewlive.com

What Is Gauge Example? Mastery Wiki Define Gauge Capability A type 1 gage study assesses only the variation that comes from the gage. Gage capability is also commonly expressed as cg and cgk. The purposes of measurement systems capability studies are to assess capability of a gauge, to. An engineer wants to certify an ultrasonic measurement system that is used to measure. Natural tolerance limits are defined as follows:. Define Gauge Capability.

From www.youtube.com

🔵 Gauge Gauge Meaning Gauge Examples Gauge In a Sentence Gauge Define Gauge Capability Cg involves the ratio between. Specifically, this study assesses the effects of bias and repeatability. An engineer wants to certify an ultrasonic measurement system that is used to measure. The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). The capability of the gage, considering both the. Define Gauge Capability.

From www.slideserve.com

PPT Gage R&R PowerPoint Presentation ID6591146 Define Gauge Capability Gage capability is also commonly expressed as cg and cgk. Cg refers to the ratio between precision and tolerance (the potential. The capability of the gage, considering both the gage variation and. A type 1 gage study assesses only the variation that comes from the gage. Reasons for poor process capability. The most common gauge capability indices are cg and. Define Gauge Capability.

From www.metabase.com

Gauge chart Define Gauge Capability Specifically, this study assesses the effects of bias and repeatability. Natural tolerance limits are defined as follows: The purposes of measurement systems capability studies are to assess capability of a gauge, to. The capability of the gage, considering both the gage variation and. Capability indices are calculated only when the gage tolerance is specified. The most common gauge capability indices. Define Gauge Capability.

From www.hydrotechnik.co.uk

Data Logging Digital Pressure Gauges Hydrotechnik UK Ltd Define Gauge Capability Capability indices are calculated only when the gage tolerance is specified. An engineer wants to certify an ultrasonic measurement system that is used to measure. Reasons for poor process capability. Process may have good potential capability. Natural tolerance limits are defined as follows: The capability of the gage, considering both the gage variation and. In this study, detailed literature review. Define Gauge Capability.

From www.slideserve.com

PPT Gage R&R PowerPoint Presentation, free download ID6591146 Define Gauge Capability The purposes of measurement systems capability studies are to assess capability of a gauge, to. In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. Natural tolerance limits are defined as follows: Cg refers to the ratio between precision and tolerance (the potential. An engineer wants to certify an ultrasonic measurement system that. Define Gauge Capability.

From support.tibco.com

How to interpret the Define Gauge Capability Specifically, this study assesses the effects of bias and repeatability. Process may have good potential capability. Capability indices are calculated only when the gage tolerance is specified. The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). An engineer wants to certify an ultrasonic measurement system that. Define Gauge Capability.

From www.chegg.com

A gage capability study was performed on the Define Gauge Capability An engineer wants to certify an ultrasonic measurement system that is used to measure. Specifically, this study assesses the effects of bias and repeatability. Cg involves the ratio between. Cg refers to the ratio between precision and tolerance (the potential. Capability indices are calculated only when the gage tolerance is specified. Reasons for poor process capability. In this study, detailed. Define Gauge Capability.

From www.presentationeze.com

Gauge Repeatability and Reproducibility. Gauge R and RPresentationEZE Define Gauge Capability In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. Process may have good potential capability. A type 1 gage study assesses only the variation that comes from the gage. Natural tolerance limits are defined as follows: The most common gauge capability indices are cg and cgk, as defined in the automotive industry. Define Gauge Capability.

From www.numerade.com

SOLVED Ten parts are measured threc times by the same operator in Define Gauge Capability Specifically, this study assesses the effects of bias and repeatability. Gage capability is also commonly expressed as cg and cgk. The purposes of measurement systems capability studies are to assess capability of a gauge, to. The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). Reasons for. Define Gauge Capability.

From slideplayer.com

DMAIC Stages and Deliverables ppt download Define Gauge Capability Process may have good potential capability. The most common gauge capability indices are cg and cgk, as defined in the automotive industry action group (aiag) msa manual (aiag, 2010). Cg involves the ratio between. Reasons for poor process capability. Capability indices are calculated only when the gage tolerance is specified. A type 1 gage study assesses only the variation that. Define Gauge Capability.

From engineeringlearn.com

Pressure Gauge Definition, Types, Uses, Parts, Applications Define Gauge Capability An engineer wants to certify an ultrasonic measurement system that is used to measure. Cg involves the ratio between. The purposes of measurement systems capability studies are to assess capability of a gauge, to. A type 1 gage study assesses only the variation that comes from the gage. Reasons for poor process capability. Gage capability is also commonly expressed as. Define Gauge Capability.

From 7esl.com

Gage vs. Gauge When to Use Gauge vs. Gage (with Useful Examples) • 7ESL Define Gauge Capability The capability of the gage, considering both the gage variation and. A type 1 gage study assesses only the variation that comes from the gage. Specifically, this study assesses the effects of bias and repeatability. In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. An engineer wants to certify an ultrasonic measurement. Define Gauge Capability.

From mungfali.com

Different Types Of Pressure Gauges Define Gauge Capability In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. Reasons for poor process capability. Process may have good potential capability. The purposes of measurement systems capability studies are to assess capability of a gauge, to. A type 1 gage study assesses only the variation that comes from the gage. Cg involves the. Define Gauge Capability.

From studylib.net

IENG 486 Lecture 15 Gage Capability Studies Define Gauge Capability Natural tolerance limits are defined as follows: The purposes of measurement systems capability studies are to assess capability of a gauge, to. Cg refers to the ratio between precision and tolerance (the potential. A type 1 gage study assesses only the variation that comes from the gage. An engineer wants to certify an ultrasonic measurement system that is used to. Define Gauge Capability.

From www.desertcart.com.cy

Buy Digital Pressure Gauge SINOCMP 25MPA/3600PSI Pressure Gauge with Define Gauge Capability Capability indices are calculated only when the gage tolerance is specified. A type 1 gage study assesses only the variation that comes from the gage. Cg involves the ratio between. Gage capability is also commonly expressed as cg and cgk. Cg refers to the ratio between precision and tolerance (the potential. Natural tolerance limits are defined as follows: The purposes. Define Gauge Capability.

From 7esl.com

GAGE Vs GAUGE When To Use Gauge Vs Gage (with Useful Examples) 7 E S L Define Gauge Capability Natural tolerance limits are defined as follows: The capability of the gage, considering both the gage variation and. Process may have good potential capability. In this study, detailed literature review of msa, gauge r&r and measurement systems capability studies, and general. Reasons for poor process capability. Gage capability is also commonly expressed as cg and cgk. The purposes of measurement. Define Gauge Capability.